Electronic heat cost allocator

A contribution by Bernd Ritter and Thomas Reichbauer, Engelmann Sensor GmbH

Smart submetering uses remotely readable heat meters (WMZ) and/or electronic heat cost allocators (EHKV) to record proportional heat consumption. In Germany, the consumption-based billing of heating and hot water costs is regulated by the Heating Costs Ordinance (HeizkostenV), which stipulates that only those EHKVs may be used whose suitability has been confirmed by an expert body. The technical standard for EHKV is DIN EN 834.

In the first section of this article, the basic interrelationships of the quite complex topic of “heat cost allocators” are explained with the help of a purely qualitative view. In the second section, the quantitative consideration, the connection between the heat output of a radiator and the functioning of the heat cost allocator is described and which restrictions and requirements result from this for the use as well as for the installation, evaluation and billing.

SECTION 1 – QUALITATIVE CONSIDERATION

While heat meters can directly measure the heat energy delivered in the heating circuit, the EHKVs mounted on the radiators only determine consumption values by means of temperature sensors, which depend on the measured temperatures and switch-on times of the radiators. In the case of the WMZ, the measured value is composed of a numerical value and a physical unit of measurement, e.g. 3500 kWh (kilowatt hours); in the case of the EHKV, the consumption value is dimensionless, i.e. without a physical unit.

Since heat cost allocators are not measuring devices for heat energy, they are also called recording devices. DIN EN 834:2017-02 describes heat cost allocators as “instrument[s] for recording the proportional heat output of radiators in usage units” (chap. 3.1) and “… recording measuring instruments for the temperature integrated over time” (chap. 4), and goes on to say that “the consumption value is an approximation of the heat emitted by the heating surface and consumed by the user during the measurement period.”

In terms of measurement, a distinction is made between heat cost allocators with regard to the measurement method, the display behavior and the design.

MEASUREMENT PROCEDURE

The measurement methods differ in the number of temperature sensors used in temperature measurement, although only the most common methods are discussed below.

Single-sensor measuring method: In the single-sensor measuring method (1F), a temperature sensor facing the heating surface, the so-called heating surface sensor, measures the temperature at regular intervals. From the so-called counting start temperature, the EHKV calculates a counting progress.

Two-sensor measuring method: In the two-sensor measurement method (2F), a heating surface sensor and a temperature sensor facing the interior are used and the temperatures measured with them are used to calculate the counting progress. Counting progresses only when the so-called count start overtemperature, a temperature difference, is reached.

Since an intentional or unintentional heat accumulation in front of the heat cost allocator would completely prevent counting progress in the worst case if this counting start criterion were used alone, the system switches to the 1F measurement method if necessary with the help of an operating status detection (heat accumulation problem).

Single-sensor measuring method with start sensor (1SF): This method also uses 2 temperature sensors. However, only the temperature of the heating surface sensor is taken into account when calculating the count progress; the room-side temperature sensor is only used to determine the count start overtemperature. As a result, the 1SF method has advantages over the 1F method in suppressing unwanted summer counting progress, but it is also subject to the heat buildup problem described for the 2F method. According to DIN EN 834, the 1SF method is assigned to the single-sensor measuring method.

BAUFORM

In terms of design, a distinction is made between compact devices and remote sensing (FF) devices. In the case of compact devices, the complete EHKV is attached to the radiator, while in the case of the remote sensor version, only a wired temperature sensor is attached to the radiator, while the housing with the computing unit is mounted on the wall at a sufficient distance from the radiator.

Remote sensor devices are used e.g. for underfloor convectors, for radiators in exposed positions or for optical reasons. Remote sensing devices can be used for all previously mentioned measurement methods. Mixed use of compact and remote sensor devices is possible when using the same heat cost allocator type and measurement method.

DISPLAY BEHAVIOR

The value shown in the display of the EHKV distinguishes between weighted and unweighted display value or between product scale and unit scale. The terms product and unit scale have been adopted from heat cost allocators based on the evaporation principle, where the level of a measuring ampoule is read off a scale.

If heater and installation-specific influencing variables are taken into account in the EHKV when calculating the counting progress, this is referred to as an evaluated display value or product scale. If the influencing variables are not taken into account, the display value is referred to as the unweighted display value or the unit scale. In the case of the unweighted display value, the above-mentioned influencing variables are then taken into account in a suitable manner during billing.

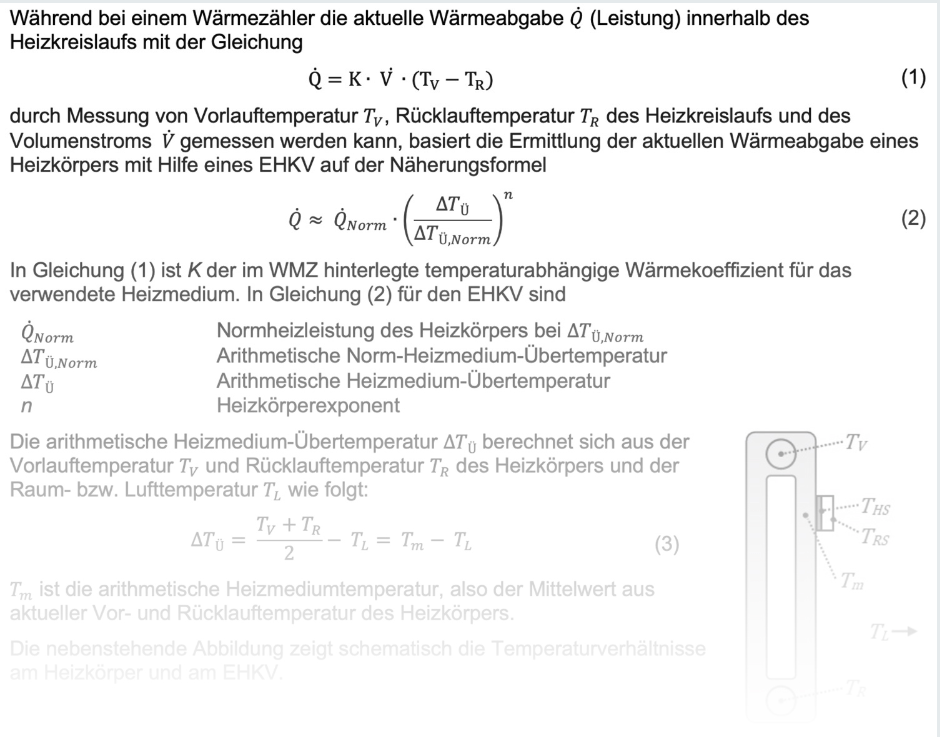

SECTION 2 – QUANTITATIVE ASSESSMENT AND REQUIREMENTS FOR THE USE OF EHKV

If you would like to read the entire article with all formulas and equations, click on the PDF download:

Download